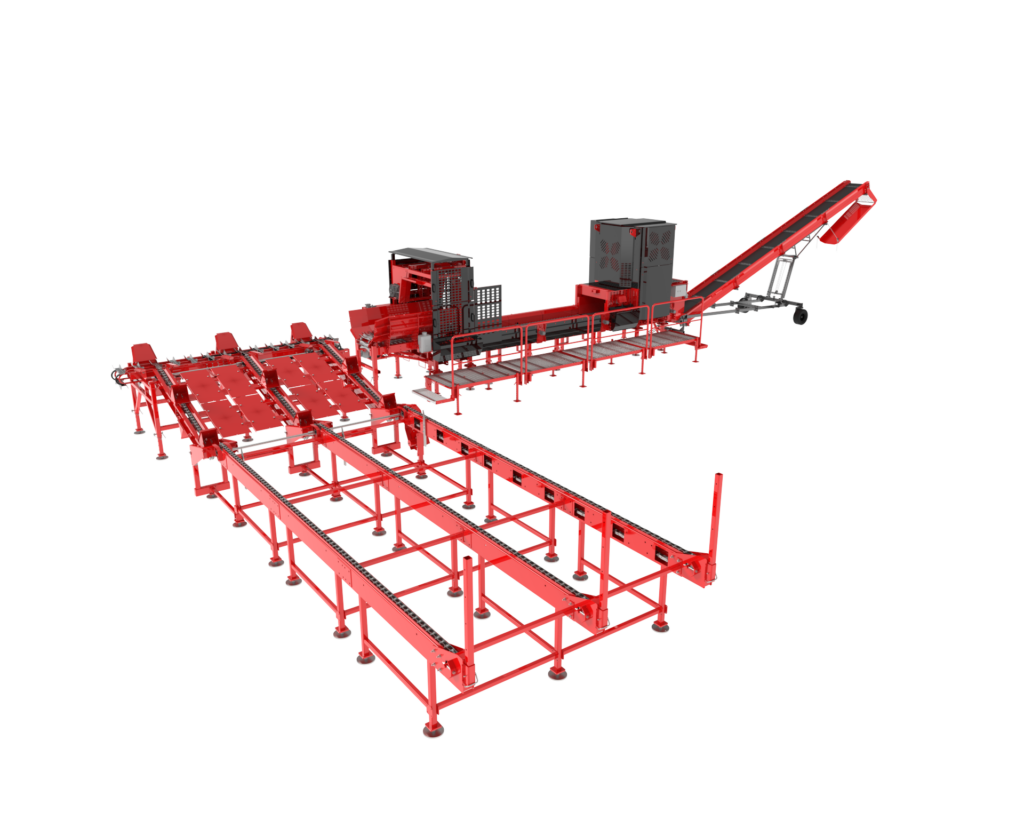

Experience cutting-edge productivity and seamless convenience with the X Firewood Factory, which transforms clapboard manufacturing into an efficient one-person job.

Welcome to the future of firewood processing with the X Firewood Factory

– a cutting-edge, semi-automatic solution designed for unparalleled

efficiency and ease of use. Engineered for industrial applications,

this one-person-operated machine includes:

- Feed 900 Log Table: Handles logs up to 90 cm (36’’) in diameter with superior performance.

- S90 Saw Machine: Offers exceptional efficiency and reliability for sawing large logs.

- X90 Log Splitter: Combines top-notch vertical splitting technology and power for perfect firewood quality.

- XL Conveyor: Capable of transporting large quantities of firewood with a built-in cleaning system.

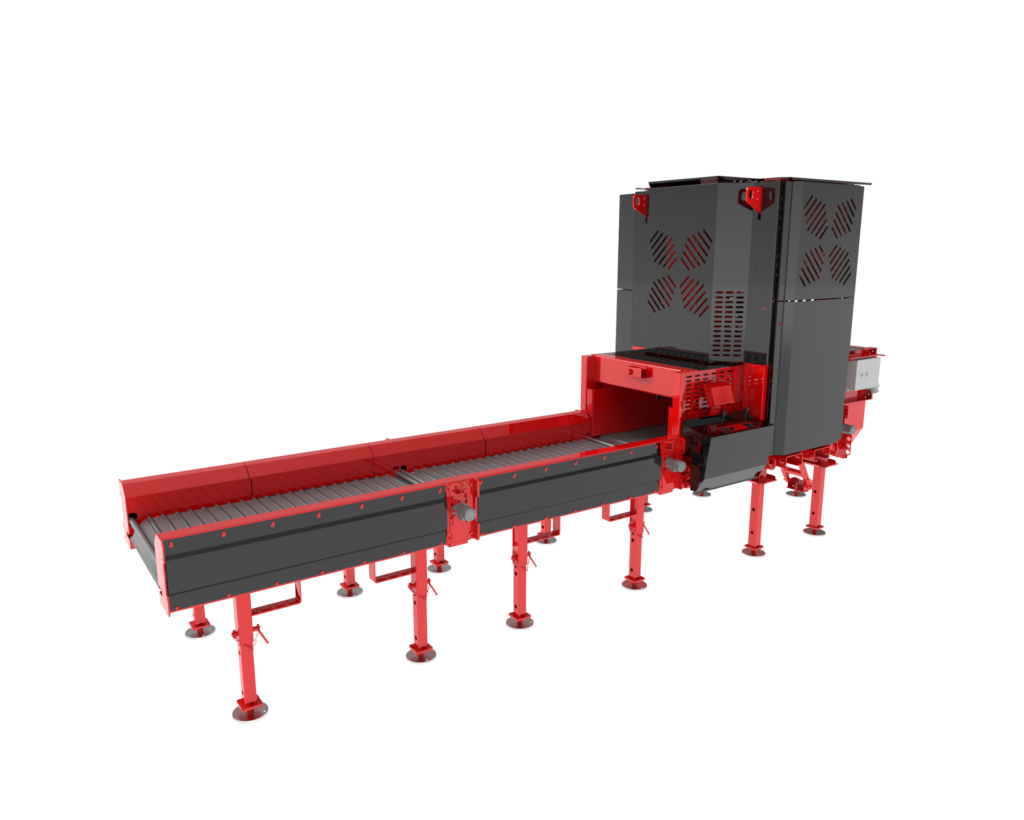

The Feed 900 Log Table delivers exceptional performance and practicality to meet the demanding needs of professionals. This feed table is specifically designed for large logs with a diameter of up to 90 cm and is equipped with a chain on bearings, ensuring smooth and reliable operation and material flow. The Feed 900 combines efficiency, durability, and user-friendliness, making it the ideal choice for professional firewood processing.

Its modular design and high-quality components ensure a long lifespan and minimal maintenance, keeping your operations running smoothly and efficiently year after year. Available in both 2- and 3-chain versions, you can choose the model that best suits your needs. Extendable up to 6 meters in length, it can handle up to 14 tons of logs.

The X90 Log Splitter combines cutting-edge technology with superior power, offering the perfect performance and quality for every firewood professional.

The splitting machine is the ideal choice for professionals who need a powerful and reliable tool for splitting wood.

Its advanced features and cutting-edge technology make it an indispensable tool that makes work more efficient and improves the quality of the end result.

The control screen allows you to determine the exact size of the firewood at the touch of a button.

The splitting machine systematically splits the wood, ensuring a perfect and uniform clapper every time, regardless of the diameter of the wood. It can split trees up to 90 cm in diameter, making it ideal for a wide range of raw material. The splitting force of up to 47 tonnes of splitting force ensures efficient and effortless splitting of wood, regardless of species. The X-blade ensures efficient and accurate splitting, always producing a uniform quality of flap. The splitting machine is fully automatic, allowing the operator to concentrate fully on feeding and cutting the trees.